Как планетарные редукторы улучшают крутящий момент, стабильность и эффективность серводвигателя?

В автоматизированных производственных линиях комбинация серводвигателя и планетарного редуктора крайне распространена. В этой статье объясняется, как планетарный редуктор преобразует высокую точность и быстрый отклик серводвигателя в стабильный, мощный и эффективный конечный выход.

Почему серводвигатели должны работать с редукторами?

Преимущества серводвигателей

Высокая точность

Серводвигатели обеспечивают замкнутый контроль положения, скорости и крутящего момента, исключая риск потери шагов, характерный для шаговых двигателей.

Высокая скорость

Серводвигатели обладают отличными высокоскоростными характеристиками, с типичной номинальной скоростью 2000–3000 об/мин.

Высокая адаптивность и перегрузочная способность

Серводвигатели могут выдерживать перегрузки до трехкратного номинального крутящего момента, что делает их идеальными для применений с резкими колебаниями нагрузки или частыми циклами пуска-останова.

Отличная стабильность на низких скоростях

Серводвигатели работают плавно на низких скоростях без шагового поведения шаговых двигателей, что делает их подходящими для применений, требующих быстрого динамического отклика.

Ограничения серводвигателей

Несмотря на свои преимущества, серводвигатели также имеют присущие ограничения:

Ограниченный крутящий момент на низких скоростях

Трудности согласования нагрузки на высоких скоростях

Пульсации крутящего момента, которые могут напрямую влиять на стабильность системы

Поэтому серводвигатели часто требуют правильно подобранного редуктора в зависимости от применения.

Как планетарные редукторы усиливают преимущества серводвигателей

Усиление крутящего момента: преобразование скорости в силу

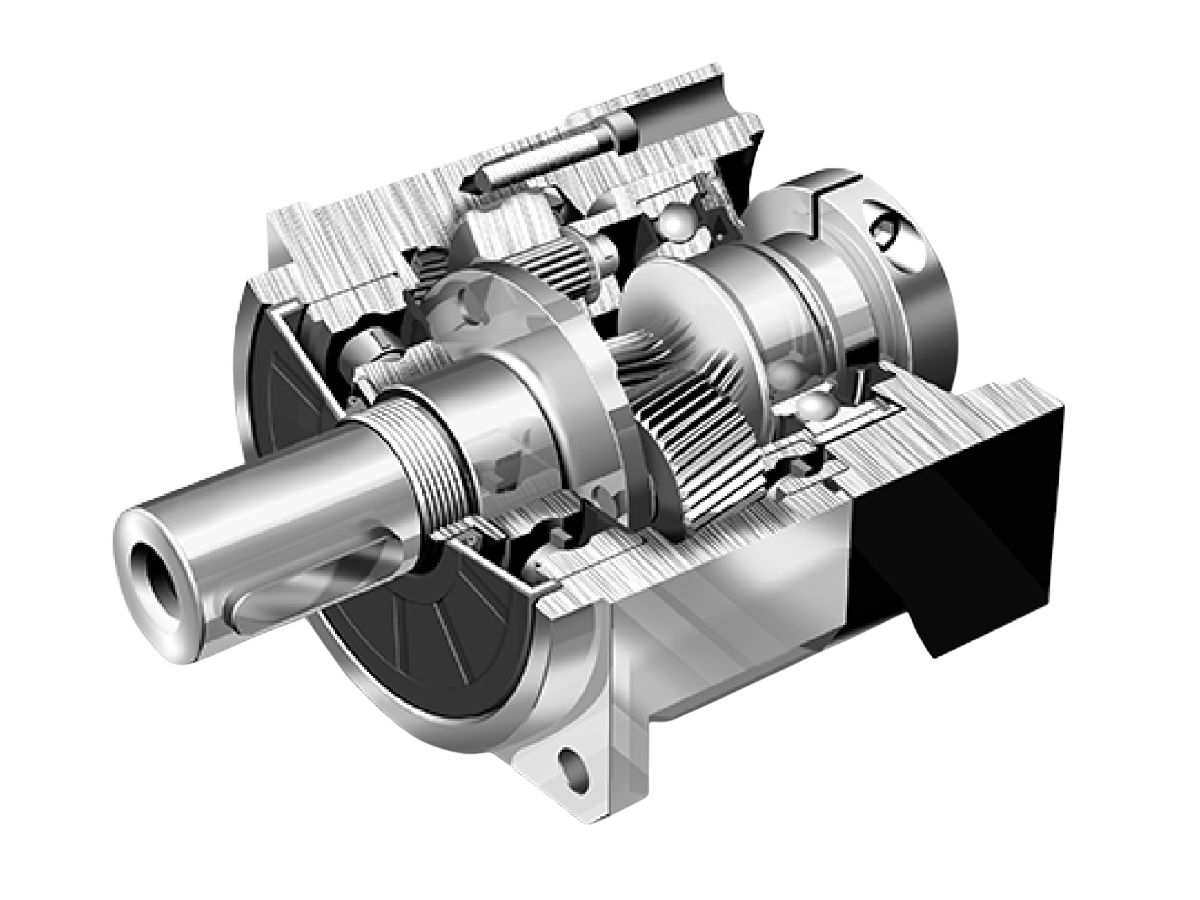

Основная функция планетарного редуктора — усиление крутящего момента.

Он преобразует высокую скорость двигателя в больший выходной крутящий момент в соответствии с передаточным отношением — проще говоря, обменивает скорость на силу.

T_{out} = T_{motor} times i times eta

Где:

i = передаточное отношение

η = КПД передачи (обычно 95–97% для планетарных редукторов)

Превосходная конструкция — ключ к стабильности

Планетарные редукторы используют несколько сателлитов, зацепляющихся одновременно, что позволяет распределить нагрузку по нескольким зубьям. Это значительно снижает нагрузку на отдельные зубья.

В результате планетарные редукторы обеспечивают:

Меньшие пульсации крутящего момента

Высокую ударопрочность

Длительный срок службы

Лучшее согласование инерции между двигателем и нагрузкой

Динамические характеристики сервосистемы во многом зависят от соотношения инерции нагрузки и инерции двигателя.

Планетарный редуктор отражает инерцию нагрузки на сторону двигателя, делая систему:

Легче настраивать

Быстрее в отклике

Более устойчивой к вибрациям и колебаниям

Почему комбинация серводвигатель + планетарный редуктор обеспечивает наилучшее соотношение цены и качества

Вариант А: Высокомощный серводвигатель с прямым приводом

Для прямого выхода 200 Нм вам потребуется серводвигатель с номинальным крутящим моментом, близким к 200 Нм.

Такой двигатель: Дорогой, Большой и тяжелый, Энергозатратный

Более того, он часто работает на низкой скорости, далеко от оптимального диапазона эффективности, что приводит к потере производительности и энергии.

Вариант Б: Маломощный серводвигатель + планетарный редуктор (пример с передаточным отношением 10:1)

С планетарным редуктором 10:1 выходной крутящий момент увеличивается в десять раз.

Теперь двигателю нужно выдавать всего 20 Нм.

Вы можете выбрать серводвигатель с номинальным крутящим моментом около 25 Нм, который может стоить в три раза меньше, чем большой двигатель с прямым приводом.

Этот меньший двигатель работает в своем высокоэффективном диапазоне средних и высоких скоростей, снижая энергопотребление и долгосрочные эксплуатационные расходы.

Сравнение стоимости и эффективности

Для применений, требующих высокого крутящего момента на низких скоростях, решение «малый двигатель + редуктор» явно превосходит прямой привод как по стоимости, так и по энергоэффективности.

Суть этой оптимальной комбинации заключается в использовании структурного рычага редуктора для достижения наилучшего баланса стоимости, пространства и эффективности.

Планетарный редуктор не ослабляет серводвигатель. Напротив, он преобразует высокоточные, быстродействующие электромагнитные управляющие возможности серводвигателя в стабильный, мощный и устойчивый выход через высокожесткую, низкозадержную и высокоэффективную механическую структуру.

Подробнее

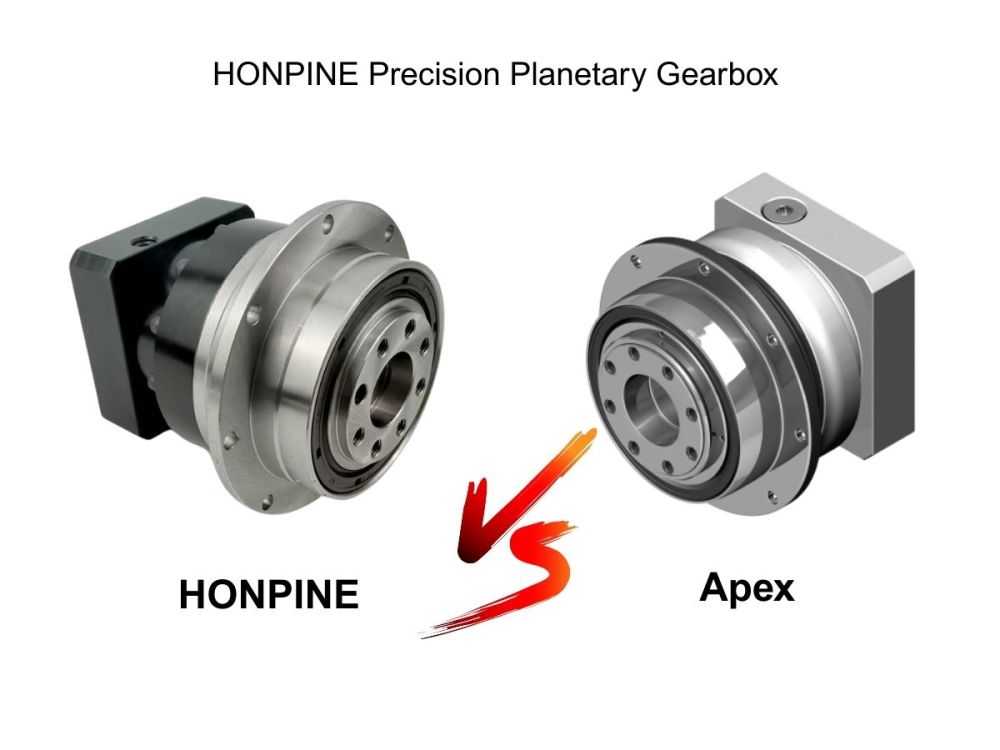

Узнайте больше о компании HONPINE и тенденциях в области точных передач.

Двойной щелчок

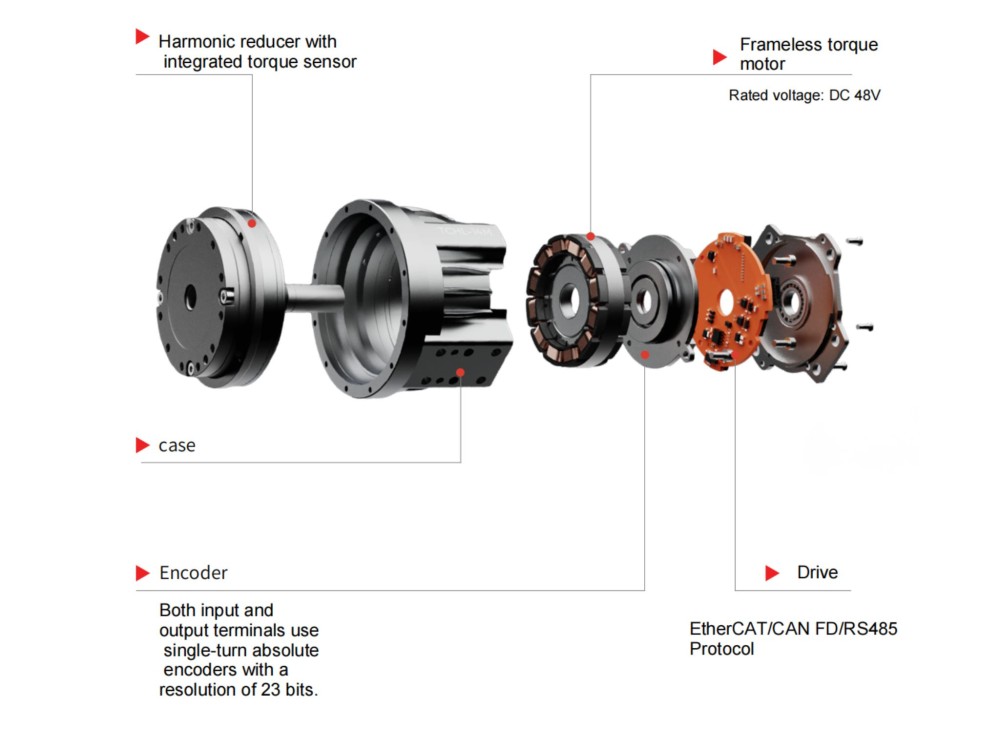

Мы предлагаем гармоничные редукторы, планетарные редукторы, моторы для роботизированных суставов, ротационные приводы для роботов, RV-редукторы, конечные эффекторы для роботов, ловкие роботизированные руки